▼

[Material & Shape]

Composition : AL Flame + STS

Size : 95(H) X 90(W) X 12000(L)

Square : AL 3,833 ㎟, STS 674 ㎟

Weight : 10.4 kg/m

[Electrical Characteristic]

Total Resistance (Before Wear) : 0.008648 [Ω/Km]

Total Resistance (Before Wear) : 1.041146 [Ω/Km]

Permissible Current : 3800A

[Mechanical Charateristic]

Coefficient of Thermal Expansion (AL) : 20 X 10-6/℃

Coefficient of Thermal Expansion (STS) : 9.9 X 10-6/℃

Moment of Inertia (mm) : INERTIA TENSOR : Ixx 4.577414e+06, Iyy 1.974847e+06

[Material & Shape]

Composition : Base + Insulator + Claw

Material : Cast Iron + Epoxy + SS400

Coating : Hop dip Galvanizing

[Electrical Characteristic]

Creeping Distance : 112 mm

Safety Distance : 75 mm

Power Frequency Withstand Voltage (Dry) : 30 kV

Light Impulse Withstand Voltage (Dry) : 15 kV

[Mechanical Charateristic]

Bending Breaking Load : 1,000 kgf

Tension Breaking Load : 2,000 kgf

[Shape and Surface Stress of Epoxy Insulator]

[Material & Shape]

Composition : Power Rail + Sliding Bar

Size : L=3000

Material : AL + STS + Cu

[Electrical Characteristic]

Permissible Current : 3800 A

Short Circuit Current : 100 kA/1s

[Mechanical Charateristic]

Coefficient of Thermal Expansion (AL) : 20 X 10-6/℃

Coefficient of Thermal Expansion (STS) : 9.9 X 10-6/℃

Max Permissible Temp : 95 ℃

Max Gap : 200 mm

Expansion Joint is installed with Max. 120m interval and the Gap is modified at surface temperature of the Power Rail

[Material & Shape]

Material : Al6063

Weight : 7.4 kg

[Electrical Characteristic]

Permissible Current : 3800 A

[Mechanical Charateristic]

Max Permissible Temp : 95 ℃

Coefficient of Thermal Expansion (AL) : 20 X 10-6/℃

[Material & Shape]

Material : Cast Iron

[Mechanical Charateristic]

Surface Coating : Hop dip Galvanizing

Yield Stress : More than 295 (N/mm2)

Tensile Strength : More than 620 (N/mm2)

Elongation : More than 9(%)

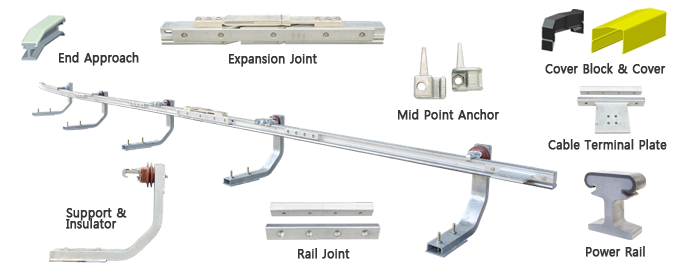

Power Rail

Expansion Joint